Fonderia Eurofondalp: innovazione e qualità nelle fusioni in alluminio

Siamo un punto di riferimento nella produzione di fusioni in alluminio, sia per il comparto industriale che per quello artigianale. Grazie ai suoi 50 anni di esperienza e all’eccellente conoscenza tecnica dei materiali, Eurofondalp è un partner di fiducia per aziende che cercano affidabilità, professionalità ed innovazione.

Siamo più di un fornitore: siamo un partner collaborativo per lo sviluppo di nuovi prodotti e riusciamo anche a portare a termine i progetti di altre fonderie per risolvere le criticità e soddisfare i nostri clienti.

Esperienza al tuo servizio

Richiedi una consulenza gratuita e incontra il nostro team di esperti dedicati che lavorano con passione e precisione per realizzare ciò di cui hai bisogno.

Perchè sceglierci Perchè dovreste affidarvi a NOI

Qualità al Top

Utilizziamo avanzati impianti radiografici industriali e spettrometri per analizzare le leghe e i getti con precisione. La vostra soddisfazione è la nostra priorità, e ci impegniamo a offrire soluzioni che rispecchiano i vostri standard.

Esperienza Pluriennale

Da 50 anni lavoriamo con dedizione nel settore delle fusioni di alluminio, diventando così un punto di riferimento. La nostra lunga storia di successo parla della nostra competenza e capacità di fornire soluzioni affidabili e durature.

Puntualità Garantita

La nostra forza è la nostra precisione. Con una consegna sempre puntuale, rispettiamo scrupolosamente i tempi concordati con voi, garantendo che i vostri progetti procedano senza intoppi.

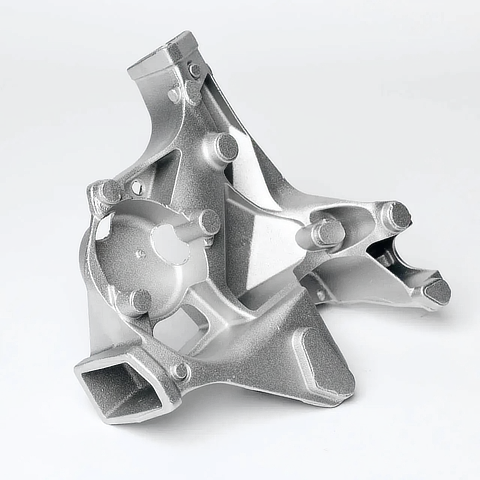

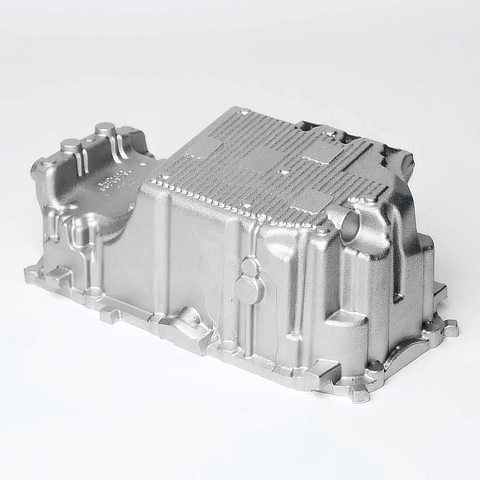

Fusioni in Alluminio

La nostra specializzazione nelle leghe leggere di alluminio ci permette di servire una vasta gamma di settori industriali con soluzioni su misura.

Piano investimenti Sviluppo e rilancio

Durante i suoi 50 anni di storia, Eurofondalp ha sempre puntato sull’innovazione tecnologica e dei processi, inserendo nuovi impianti.

Recentemente, grazie al sostegno della Regione Lombardia, l’azienda ha anche implementato un piano di investimenti finalizzato al miglioramento delle operazioni. I miglioramenti hanno coinvolto diversi aspetti del processo produttivo, inclusa la preparazione delle terre ed il trasporto dei materiali.

250 + Clienti Soddisfatti

250 + Clienti Soddisfatti Il cliente al centro Che cosa pensano di noi e dei nostri servizi

Abbiamo guadagnato la fiducia dei nostri clienti perché hanno trovato in noi affidabilità, serietà e naturalmente umanità.

I nostri clienti ci apprezzano soprattutto per la nostra gestione efficiente dei progetti, per l’attenzione che dedichiamo ai dettagli, per il valore della nostra esperienza decennale e per l’impegno che mettiamo nel raggiungere sempre alti livelli di qualità.

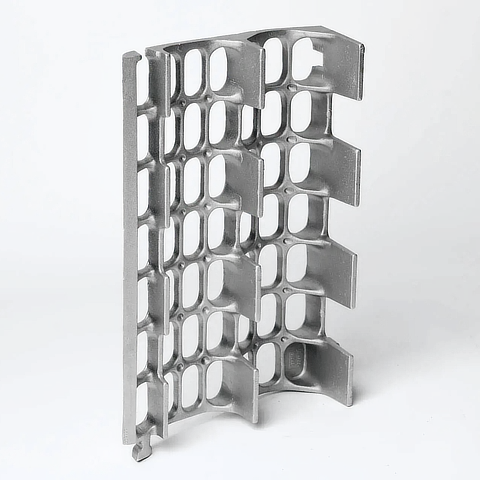

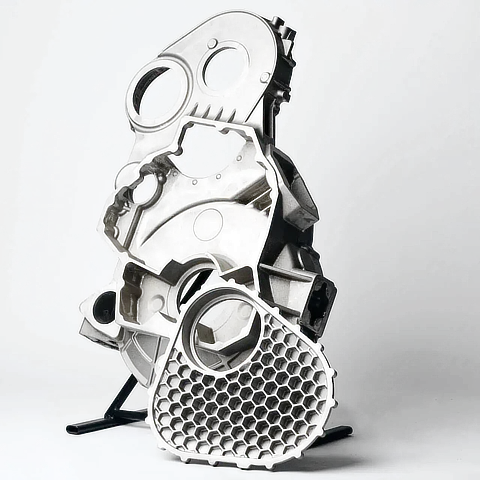

Stampi Produzione delle fusioni in alluminio

I nostri reparti

Benvenuti nei reparti produttivi di Eurofondalp, dove l’arte della fonderia prende vita

La nostra fonderia è suddivisa in diversi reparti, ognuno specializzato in operazioni specifiche, garantendo un controllo accurato e una produzione ottimale. Qui la tradizione artigianale si fonde con la tecnologia moderna per creare fusioni in alluminio di prima classe.

Abbiamo un impianto con robot di colata, uno di formatura a terra, uno semiautomatico ed un laboratorio interno.

Ci sono poi il reparto di animisteria, di formatura manuale e l’area fusoria.

Recensioni Che cosa pensano di noi e dei nostri servizi